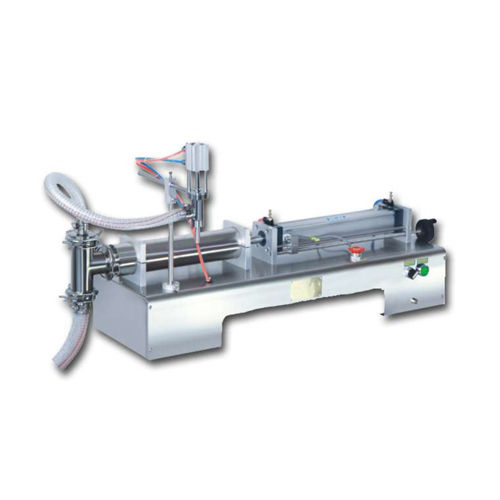

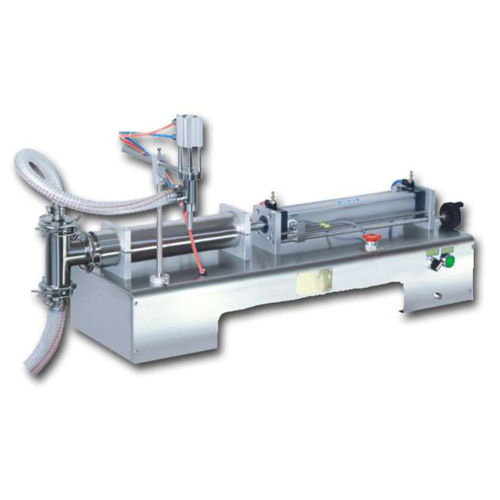

GC-A Liquid Filling Machine

GC-A Liquid Filling Machine Specification

- Material

- Stainless Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Frequency Speed Control

- Drive Type

- Electric

GC-A Liquid Filling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About GC-A Liquid Filling Machine

It is ideal semi-auto Liquid filling equipment for medicament, light industry, food, pesticide and other special industry. Adopting advanced pneumatic parts from Taiwan AIRTAC. Simple operations are the main feature of machine. The piston and cylinder are made up of 304 stainless steel and Polytetra fluorothylene (PTEF). It accords with GMP requirement. The filling range and speed are adjustable. Filling unit has function of leaking-proof, silk nuzzling-proof. Machine is able to change to multi-head, burst-proof and flood-proof filling unit according to requirement of customers.

Specification

|

Model |

GC-A |

|

Filling Type |

One Nozzle |

|

Air Supply |

400L/min 0.6 Mpa |

|

Filling Range (m) |

10-100,50-500,100-1000ml |

|

Efficiency(Bottle/ hour) |

600-1500 |

Efficient and Adjustable Filling Solution

The GC-A Liquid Filling Machine features frequency speed control, enabling operators to fine-tune filling speeds according to the product type and production needs. Its semi-automatic design integrates manual oversight with automated precision, offering a balance between flexibility and efficiency. Stainless steel construction guarantees longevity and easy cleaning, catering to industries where hygiene is paramount.

Versatile Applications for Indian Manufacturing

Designed for a wide range of industries, this filling machine finds its place in food processing, beverages, pharmaceuticals, chemicals, and cosmetics. Indian suppliers and manufacturers benefit from its adaptability to different container sizes and liquid types. The GC-As reliable performance contributes to reduced product waste and higher productivity, supporting consistent quality in bottled goods.

FAQs of GC-A Liquid Filling Machine:

Q: How does the GC-A Liquid Filling Machine operate?

A: The GC-A operates semi-automatically, requiring manual placement of containers, after which the machine fills them using an electric drive and frequency speed control to ensure accurate and consistent dosing.Q: What types of liquids can this machine fill?

A: Thanks to its adjustable speed and durable stainless steel construction, the GC-A can handle a variety of liquid products, ranging from thin beverages to more viscous solutions like oils or syrups.Q: When is it ideal to use a semi-automatic filling machine like the GC-A?

A: This machine is particularly suitable for small to medium-sized businesses with moderate production volumes that require both precision and flexibility without the need for computerized automation.Q: Where can the GC-A Liquid Filling Machine be installed?

A: It is designed for installation in industrial settings such as manufacturing plants, bottling units, or packaging lines throughout India, supported by local suppliers and manufacturers.Q: What is the filling process with this machine?

A: Operators manually set the containers under the filling nozzle, and the machine dispenses the liquid automatically. The speed and volume are controlled via the frequency speed control system for consistent results.Q: How does the frequency speed control benefit users?

A: Frequency speed control allows operators to adapt the filling rate to different liquid types and production demands, improving efficiency while minimizing product spillage and wastage.Q: What are the main benefits for Indian manufacturers using this machine?

A: Manufacturers benefit from reduced labor costs, reliable bottle-to-bottle consistency, increased throughput, and adherence to hygiene standards, all provided by a machine built for the Indian industrial environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filler Machine Category

Single Nozel Digital Liquid Filling Machines

Feature : Other, High precision, easy operation, low noise, stainless steel body, antidrip, programmable fill volume

Drive Type : Other, Electric motordriven peristaltic pump

Automatic Grade : SemiAutomatic

Material : 304 Stainless Steel housing, foodgrade silicone tubing

Computerized : Yes

Liquid And Paste Filling Machine

Minimum Order Quantity : 1 Unit

Feature : High Efficiency

Drive Type : Electric

Automatic Grade : SemiAutomatic

Material : Stainless Steel

Computerized : No

Industrial Liquid Filler Machine

Minimum Order Quantity : 1 Unit

Feature : High Performance

Drive Type : Electric

Automatic Grade : SemiAutomatic

Material : Stainless Steel

Computerized : No

GST : 27AKGPN2087A1ZC

|

Kiran Traders

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry