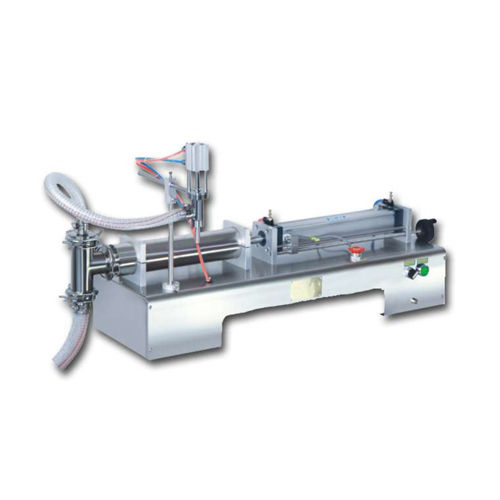

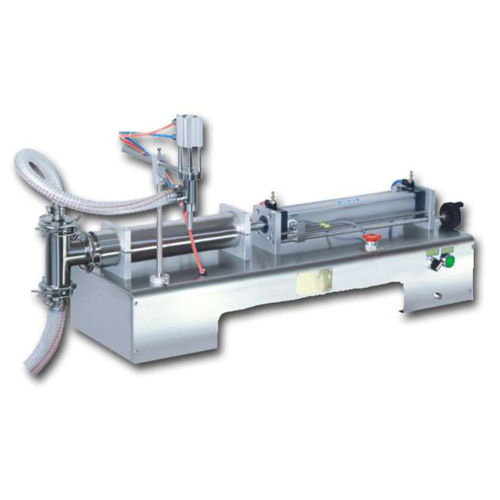

Single Nozel Digital Liquid Filling Machines

Single Nozel Digital Liquid Filling Machines Specification

- Product Type

- Single Nozzle Digital Liquid Filling Machine

- Material

- 304 Stainless Steel housing, food-grade silicone tubing

- Application

- Pharmaceutical, food & beverage, chemical, cosmetic liquids filling

- Packaging Material

- Bottles, vials, jars, containers

- Computerized

- Yes

- Automatic Grade

- Semi-Automatic

- Control System

- Microcontroller-based digital control

- Drive Type

- Electric motor-driven peristaltic pump

- Voltage

- 220V AC, 50/60 Hz

- Weight (kg)

- 8 kg

- Dimension (L*W*H)

- 400 mm x 300 mm x 250 mm

- Capacity

- 2 ml to 3500 ml per fill

- Feature

- High precision, easy operation, low noise, stainless steel body, anti-drip, programmable fill volume

- Color

- Silver

- Power Consumption

- <80W

- Display

- LCD digital display for settings and readout

- Nozzle Diameter

- 8 mm (customizable on request)

- Mobility

- Desktop/benchtop portable design

- Control Panel

- Touch membrane-type control keys

- Compatible Liquid Types

- Suitable for low to medium viscosity liquids, non-corrosive liquids

- Filling Accuracy

- ±1%

- Filling Speed

- 10-40 bottles/minute (varies with volume and liquid viscosity)

- Operation Mode

- Manual and automatic cycling

- Operating Temperature Range

- 5°C to 40°C

About Single Nozel Digital Liquid Filling Machines

Short Description

- Single Head Manual Liquid Filling Machine

- Maximum speed 3 liter/min (Approx)

- 80 Watts Power

Manual 10 to 4000 ml Single Nozzle Digital Liquid Filling Machine

Descriptions :

Digital Liquid machine with SS Body and single Nozzle, Maximum speed 3.2 liter/min. It can fill liquid, oil, juice, perfume, ink, water, etc. for all containers such as bottles, jars, cans, etc. Widely used in cosmetics, drinks, chemical, medical, food industry, etc. which can highly improve productivity and product quality. Apply for oil, washing liquid, acid liquid, liquid filling high etching solution, highly corrosive liquid.

Features :

- The pump head is made of stainless steel which is an anti-erode glove, and anti-corrosion.

- The filling range can be from 5 ml depending on the filling time you set.

Specifications :

- Model : APM 280

- Product Type : Single-Head Liquid Filling Machine

- Voltage : 220V

- Frequency : 50/60Hz

- Power : 80W

- Deviation : -/+ 2%

- Cooling by : Air cooling

- Capacity : 10-4000 ml

- Maximum speed : 3 liter/min (Approx)

- Size (L x W x H) : 350 x 320 x 200 mm

- Automation Grade : Manual

Usage/Applications : Liquid Filling, especially for oil, Washing fluid, Acid-base fluid, corrosive liquid, etc.

Note : Fluid Consistency should be thin and run Quickly through the prongs of the fork.

Kiran traders deals in various types of Packaging Machinery. Wide variety of Liquid & Paste Filling Machines are equipment used in different industries like cosmetics, pharmaceutical, food & beverages industries where liquids are to be packed or filled up in various types of containers. Some of these liquids have high viscosity or thickness and hence require special machines to fill up the containers.

Country of origin: China

Superior Precision and Versatility

Engineered for high precision and flexibility, this machine accommodates a wide range of liquid types, including pharmaceutical syrups, essential oils, cosmetics, and food extracts. With a customizable nozzle and easy-to-use control keys, users can adapt operations to various container sizes and production needs. Its semi-automatic modes support both manual and automatic cycling, optimizing performance and boosting productivity.

User-Friendly Digital Controls

Equipped with an intuitive LCD digital display and membrane touch panel, the filling machine enables quick adjustments and consistent monitoring. Settings for fill volume and cycle modes are easily programmable, ensuring operational efficiency. The microcontroller-based system guarantees accuracy and repeatability, reducing human error and product wastage.

Compact, Portable, and Hygienic Design

With its benchtop-friendly size (400 x 300 x 250 mm) and 304 stainless steel construction, this machine is both robust and easy to clean. The use of food-grade silicone tubing enhances hygiene, making it suitable for industries demanding high sanitary standards. Low power consumption and quiet electric motor operation make it ideal for a variety of environments.

FAQ's of Single Nozel Digital Liquid Filling Machines:

Q: How does the Single Nozzle Digital Liquid Filling Machine achieve high filling accuracy?

A: The machine utilizes a microcontroller-based digital control system in combination with an electric motor-driven peristaltic pump, ensuring precise dispensing with an accuracy of 1%. Programmable fill volumes and anti-drip nozzle mechanisms further minimize product loss and maintain consistent results.Q: What types of liquids and containers can this filling machine handle?

A: This model is designed for low to medium viscosity, non-corrosive liquids such as syrups, cosmetic lotions, oils, and beverages. It's compatible with a variety of packaging materials, allowing for easy filling of bottles, jars, vials, and other containers ranging from 2 ml to 3500 ml per fill.Q: When is it best to use manual versus automatic operation mode?

A: Manual mode is ideal for small batch runs or when varying fill volumes are needed, providing hands-on control over each dispensing cycle. Automatic mode is suitable for repetitive, larger scale operations where consistent fill volumes and higher throughput (up to 40 bottles/minute) are required.Q: Where can the filling machine be placed and operated?

A: Its desktop and benchtop portable design allows for easy installation on most work surfaces in labs, small factories, or production lines. Weighing only 8 kg and featuring a compact footprint, the machine is convenient for environments with limited space.Q: What is the process for setting up and adjusting the filling volume?

A: Users can program the desired fill volume directly through the membrane touch control panel. The LCD display offers clear readout and feedback, making it simple to set, save, or modify parameters for different production requirements.Q: How does this machine benefit small to medium sized businesses?

A: With its high precision, user-friendly controls, low noise, and rapid filling speeds, the machine streamlines filling operations, reduces labor costs, and minimizes product wastage. Its versatility and easy maintenance also ensure reliability for growing businesses in multiple sectors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filler Machine Category

Industrial Liquid Filler Machine

Minimum Order Quantity : 1 Unit

Control System : Frequency Speed Control

Material : Stainless Steel

Drive Type : Electric

Computerized : No

Automatic Grade : SemiAutomatic

Liquid And Paste Filling Machine

Minimum Order Quantity : 1 Unit

Control System : Frequency Speed Control

Material : Stainless Steel

Drive Type : Electric

Computerized : No

Automatic Grade : SemiAutomatic

GC-A Liquid Filling Machine

Minimum Order Quantity : 1 Unit

Control System : Frequency Speed Control

Material : Stainless Steel

Drive Type : Electric

Computerized : No

Automatic Grade : SemiAutomatic

GST : 27AKGPN2087A1ZC

|

Kiran Traders

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry